SPIR

A collaborative platform ensuring efficient data flow, governance and transparency

About

The new digital SPIR solution is a collaborative platform between operators, contractors and suppliers, to ensure efficient data flow, governance, and transparency between all entities in the SPIR process

SPIR (“Spare Parts and Interchangeability Record”) is ensuring spare part recommendations for projects, modifications and operations. The SPIR process consists of activities from operators, contractors and suppliers, and needs to be delivered to support repair- and maintenance strategy for installed and stock equipment.

Over the last years, a “digital SPIR initiative” has been spearheaded by several industry participants, including operators, contractors, suppliers and Offshore Norge.

By shifting from the traditional SPIR process using excel sheets, operators, contractors and suppliers can;

- Standardise workflows, roles and responsibilities

- Improve communication between operators, contractors and suppliers through a common interface

- Reduce time and resources required in SPIR

- Enhance data quality and facilitate reusability

- Benefit from APIs and data from associated and interconnected services (e.g., EqHub, Virtual Inventory, internal ERP systems)

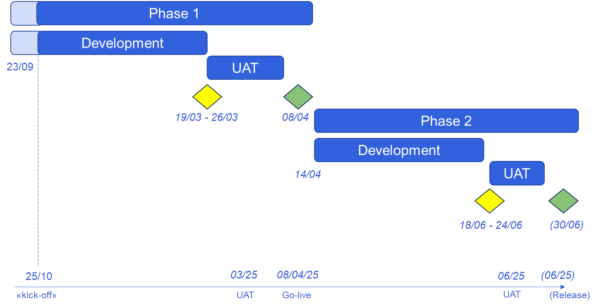

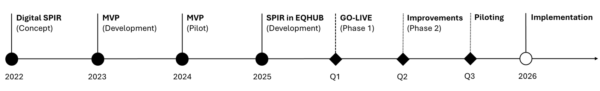

Timeline and roadmap

History

| 2025: | Solution deployed as EqHub module in April. Phase 2 (improvements) delivered in June. Solution ready for industry. |

| 10.2024: | Project starts (kick-off). |

| 06.2024: | Decision made to make a shift in technology and service provider. |

| 01.2024: | The project is in the piloting phase of the MVP for I-SPIR. Stakeholder involvement from the following companies: Emerson, Score, IKM Flux, Equinor, Vår Energi and Aker BP. |

| 12.2023: | The project is in the user acceptance testing (UAT) of the MVP for I-SPIR to verify that all functional requirements are met. |

| 2023: | Development and UAT. |

| 2022: | Conceptualisation and early development of I-SPIR solution. |

Benefits

Communication and collaboration between entities in the whole SPIR process are simplified through one common platform, and enables real time collaboration

Improved work efficiency.

Improved material master data.

Shortened data delivery schedules.

Improved revisioning.

Achieved regulatory compliance.

Mitigated risks.

Saved time and resouces.

The SPIR process

A brief history of the SPIR process

|

|

|

|---|---|---|

| The first SPIRs were handwritten. | Later, Excel sheets were used. | Now, one common platform for SPIR processing can be used, integrating data from EqHub, VI and ERP systems. |

Guides and information

Documents and media

Documents

Projects in EqHub – Introduction and purpose

Show and tell sessions (project development)

EqHub

EqHub serves as a single, controlled, central source of vendor documentation.

FAQ

When was the solution launched?

Who is behind the initiative?

Will suppliers have to provide part information in both EqHub and SPIR?

How is commercial information going to be processed and/or protected?

Who can access data and information submitted in SPIRs?

Will deliveries of SPIR and overall parts data have an effect on document requirements in EqHub?

How will this solution relate to Virtual Inventory (VI), Critical and Loop?

Will an operator’s master data be accessible in SPIR?

Will there be APIs available?

How can we get involved?

Support

Contact information

André Oaland, Project manager, SPIR

+47 984 75 095 / andre.oaland@external.offshorenorge.no

Øystein Arvid Håland, Project manager, Collaboration

+47 918 76 645 / oystein.haland@offshorenorge.no